HOW WE SORT WASTE

We sort your waste into more than 40 different fractions

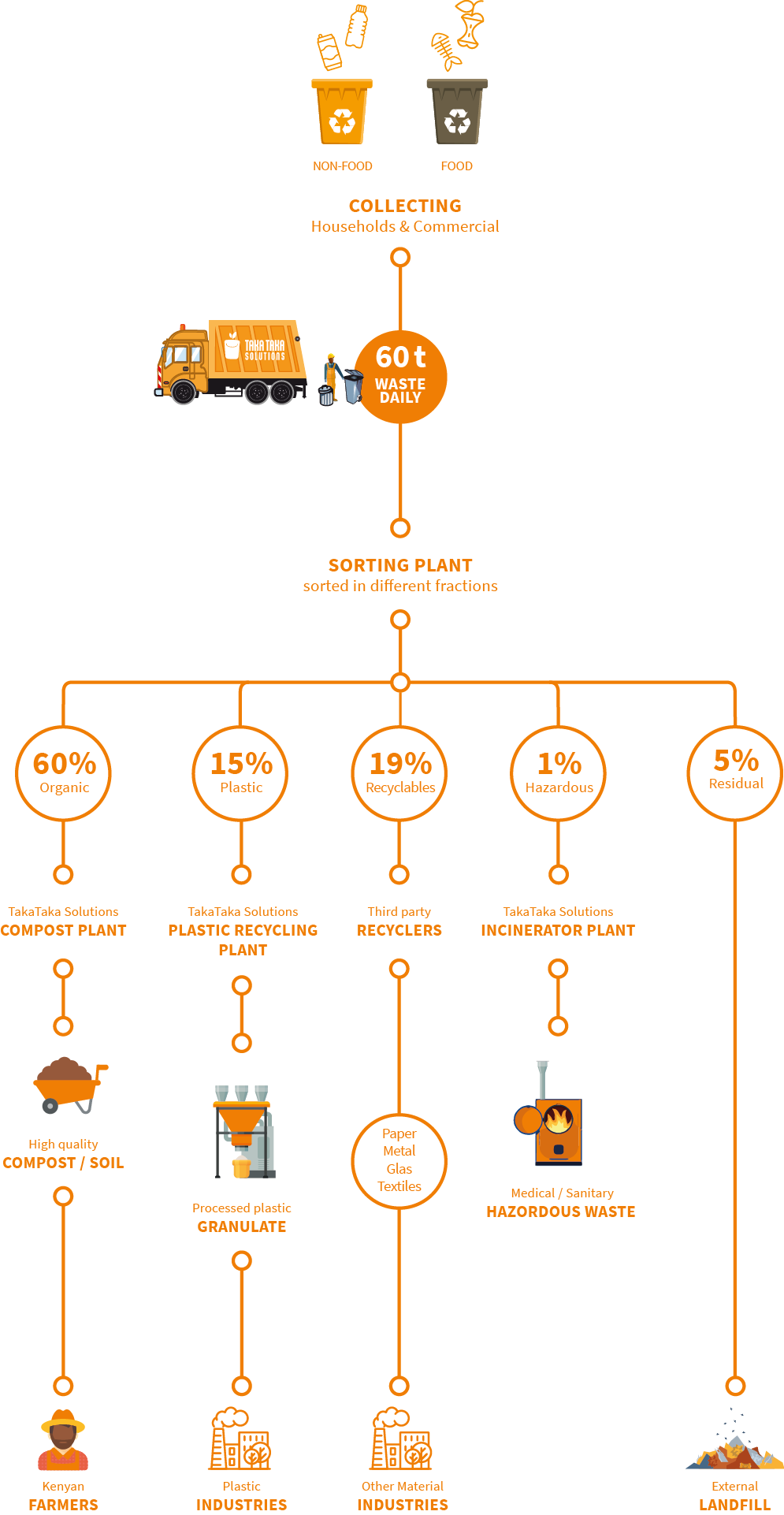

Recycling is the foundation of our waste management model. This is why waste separation and sorting are essential in what we do. Only when waste is sorted well and not overly contaminated can it be recycled.

After collection we take the waste to one of our sorting plants. Here we always try to sort out as much waste as possible for onward recycling. Using conveyor belts and other machinery our trained staff sort the incoming waste into more than 40 different waste fractions: paper, cardboard, plastic containers & packaging, styrofoam, glass, metal, aluminum, shoes, textiles and many more fractions. Most of these materials are then compacted for easier storage and onward transport.

We take the sorted organic waste to our own composting plant. Plastic containers and packaging go to our own plastic recycling plant. We take other materials (paper, metals, glass) to third-party recyclers where they are processed into new raw materials.

We currently operate three sorting sites where we employ more than 150 staff.

How we recycle waste

We turn plastic waste into valuable raw materials for local industries

We are also active in recycling ourselves materials that others don’t recycle. In this way we can guarantee that as much of the waste we collect gets a second life.

At our plastic recycling plant we convert a variety of plastic containers, cups and packaging into valuable new raw materials for Kenyan manufacturing industries. Our recycling plant is the only recycling plant in Kenya for single-use light plastic containers (i.e. yoghurt cups, fast-food trays).

Our plants turn plastic products into flakes. We optionally can also turn the materials into new pellets. These are the steps:

- Pre-sorting and quality control

- Crushing into smaller flakes

- Turbo washing

- Hot-washing at 90 degrees Celsius

- Washing and rinsing

- Drying and label removal

- Pelletising (melting of flakes into pellets)

How we compost waste

Turning organic waste into a high quality natural soil amendment

At our composting plant we process organic and garden waste into high quality compost, a natural soil amendment. The compost is then used by urban households and farmers across Kenya to improve their soil fertility.

Compost helps replenish soil fertility by increasing the soil organic matter. Its nutrient composition is high and its benefits include not only increased crop growth but also water retention, reduced need for chemical fertilizers and suppression of soil-borne diseases and pests.

Our compost is produced at our composting plant through a variety of steps. First we sort the organic waste during multiple steps to ensure clean input materials. The organic waste is then set-up into windrows, long rows, which are frequently turned by a windrow turner to achieve aeration. After about three months the ready product is sieved and checked for quality.